It has been a few years since real work on the SIAM was done. The Elden’s keep the shop busy but with this pandemic and waiting for some racing parts I decided the catch up some SIAM work.

First I rebuilt the the Crosley Steering box with new bushings and seals from Service Motors, https://www.servicemotors.net/. Then I tackled the fun job of the Crosley front axle King Pins. The King pins required some tooling to allow reaming to fit and maintaining the alignment of the top and bottom. So I built this reamer tool.

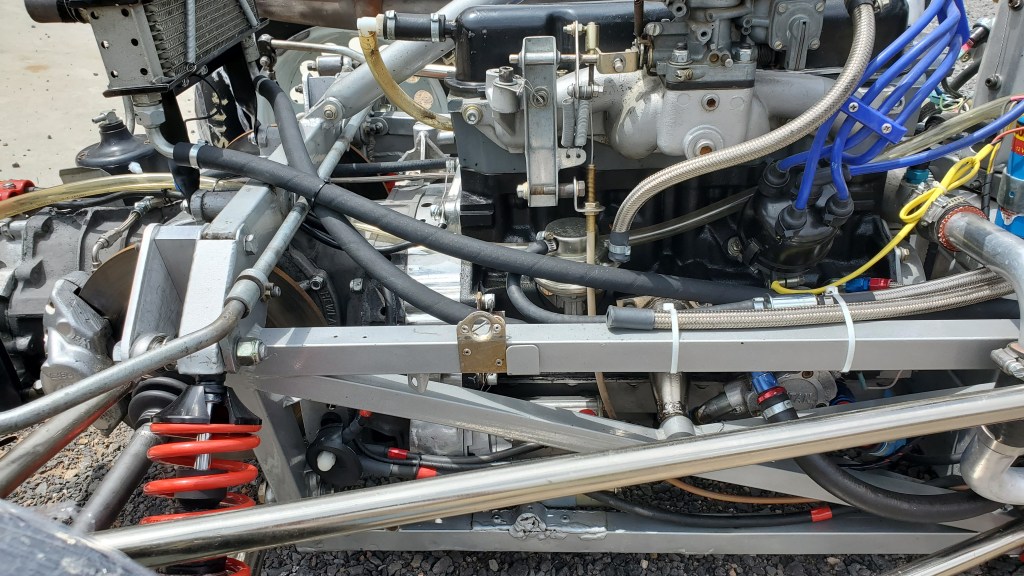

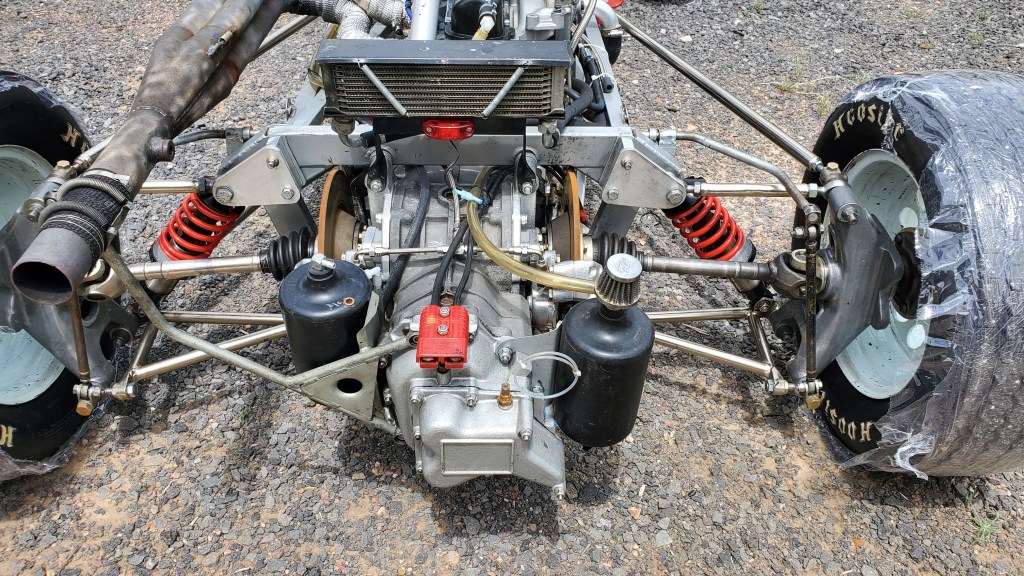

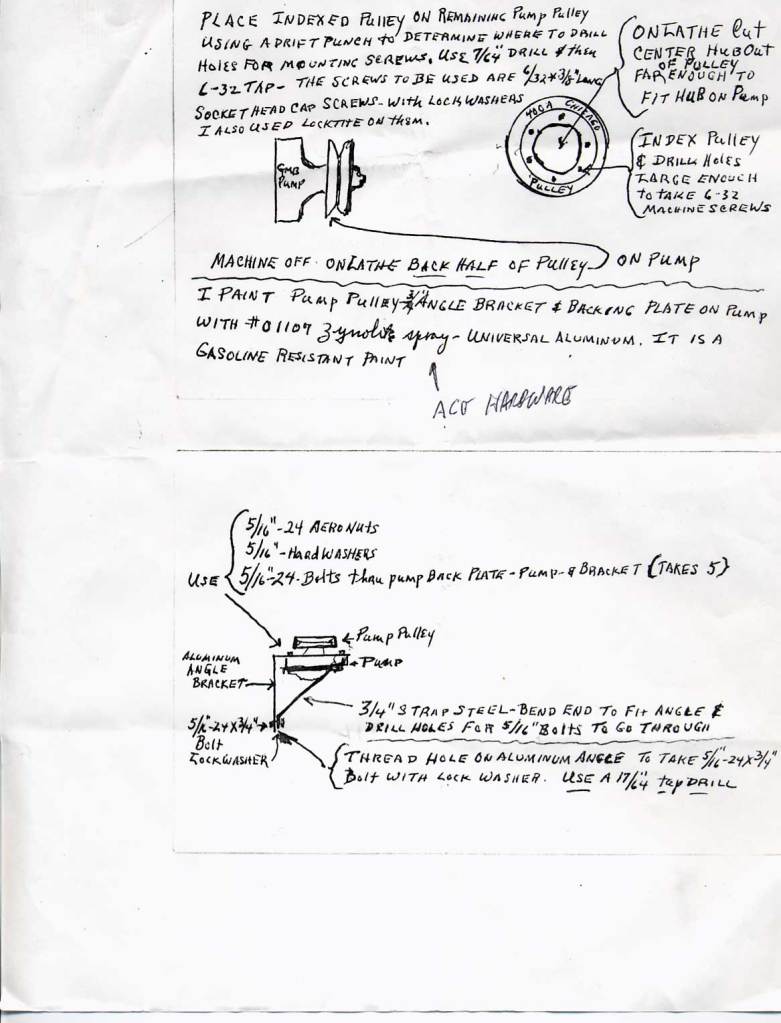

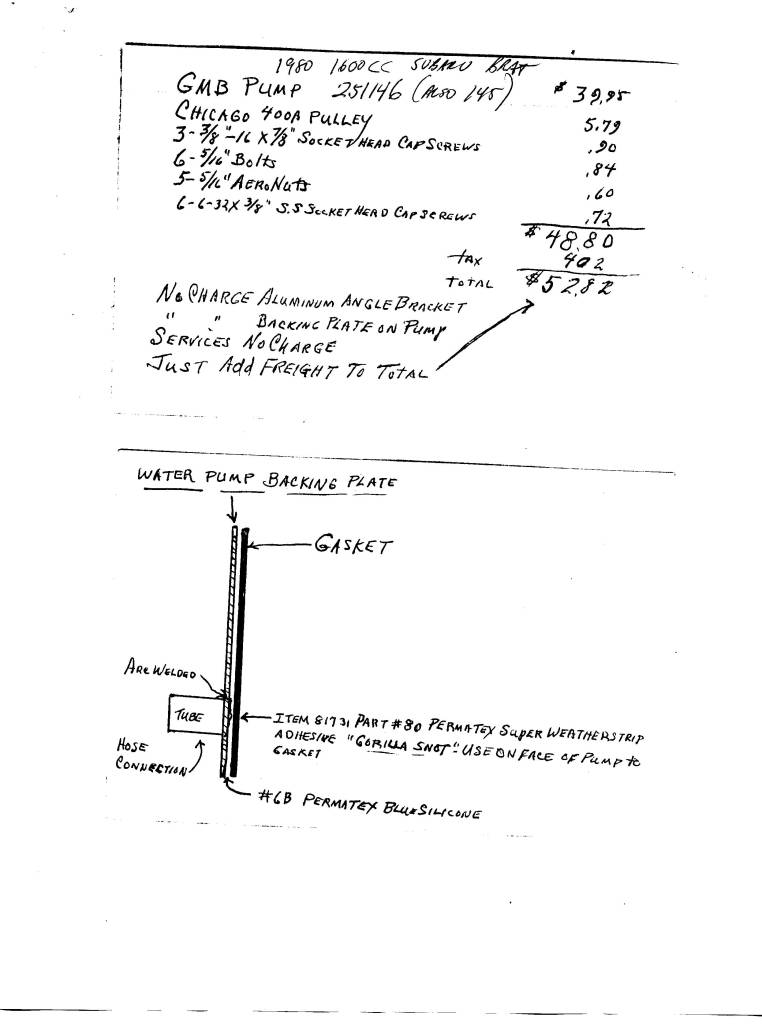

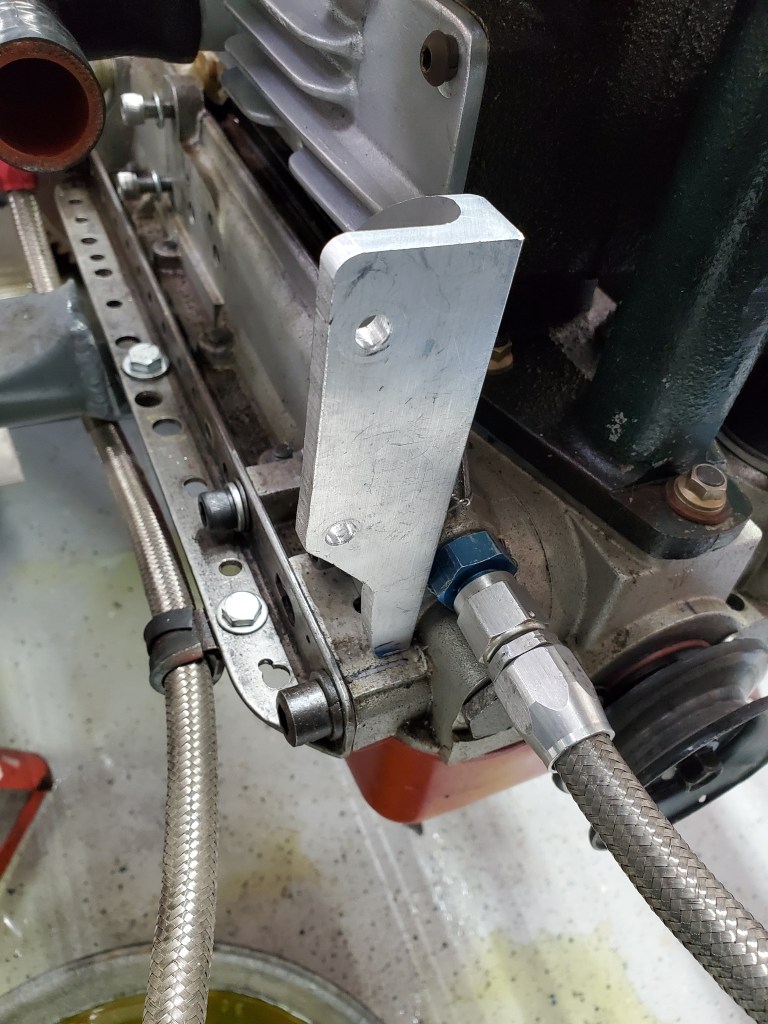

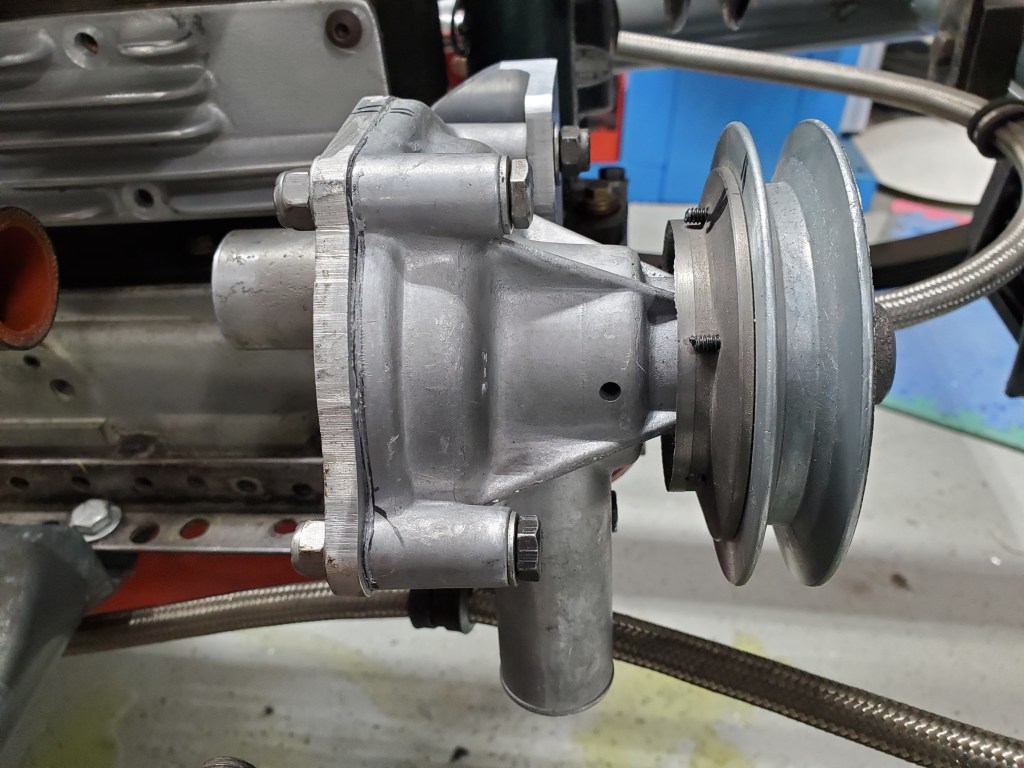

A project I started December 2017 was to convert to a Subaru Brat water pump. I had previously made the pulley, https://lchrestoration.com/category/1954-h-mod-siam/. Now I needed to make a bracket to hold the pump and complete the plumbing.

The complete installation:

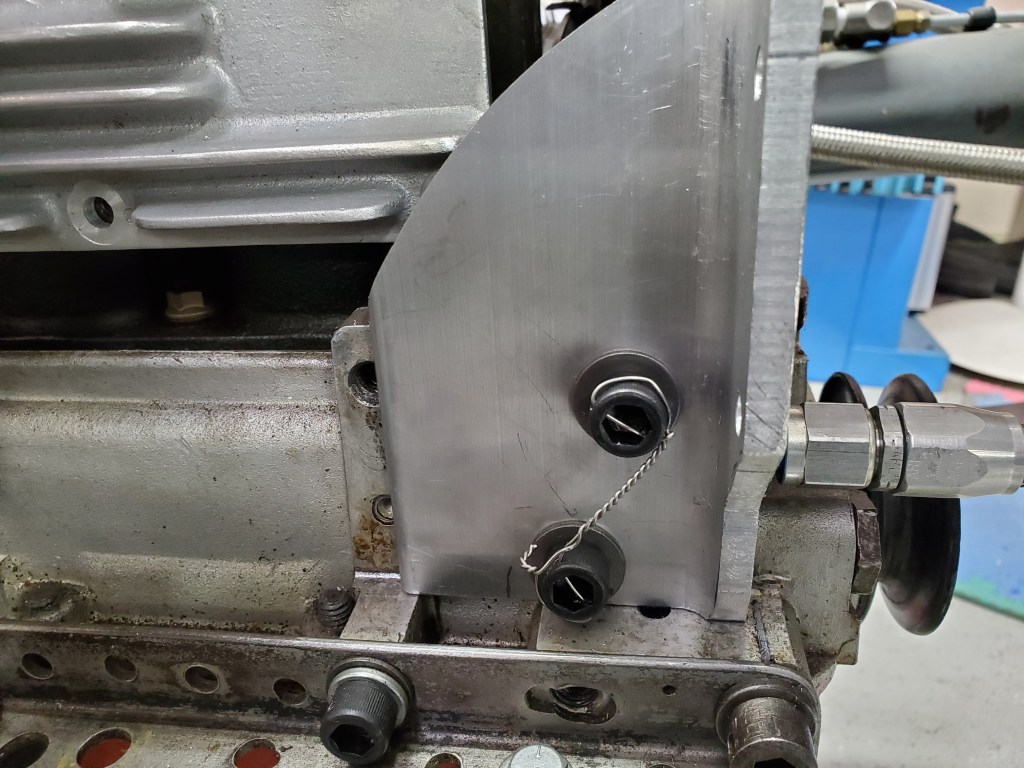

Finally, I reinstalled the Crosley front axle. The SIAM is right hand drive and as such the front axle is turned around 180 degrees. That in itself sees to be okay. But I found that the front friction lever shocks were binding up the front leaf springs. So I built a new mounting system allowing the lever shock to move without binding. Wish I had taken a picture of the original but here is the new.

Another thing found was that castor seems off with reversing the axle. Will update this later as the work isn’t done. The following picture shows a castor adjustor on the Crosley Fibersport waiting for restoration here. What is weird it is on the top of the leaf spring and I’m not convinced that it actually adjusts. I would think it belongs on the bottom of the leaf spring. Once the wheels are back on the ground I can confirm all of this.

Will update soon the castor resolution soon.